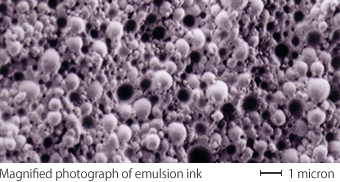

The RISOGRAPH uses an emulsion ink comprised of a mix of oil and water bases. Emulsion is a process in which an emulsifier is used to combine two incompatible substances by dispersing one throughout the other and preserving the result in a stable state. Some familiar examples include mayonnaise, butter, milk, acrylic paint, wood glue, and latex. The ink used by the RISOGRAPH is a water-in-oil emulsion, wherein water is dispersed in oil like butter.

The photograph shows emulsion ink under an electron microscope. Many minute particles of water can be observed within the oil. Pigment and surfactant is added to the combination of water and oil to yield emulsion ink.

The optimal mixing ratio of oil and water is carefully determined to enable stable storage in print drums while printing is not taking place, and to provide maximum image quality together with quick drying.

One other advantage of emulsion ink is that it is less sensitive to changes in temperature or other environmental aspects.

An ink that does not dry out inside the printer, yet dries quickly after printing

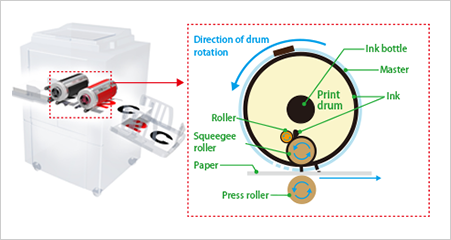

In the RISOGRAPH printer, the master used for printing is wrapped around the print drum. Printing takes place by applying pressure to the paper passing through the printer with a press roller as the drum is rotated.

When no printing is done, water can evaporate from the ink remaining in the print drum, resulting in deteriorating ink quality. This deterioration may lead to problems such as faint print.

The emulsion ink used by the RISOGRAPH has been developed to keep the deterioration of the ink to a minimum, so it can recover functionality and be able to print when needed.

Quick absorption into the paper, giving beautiful printed images

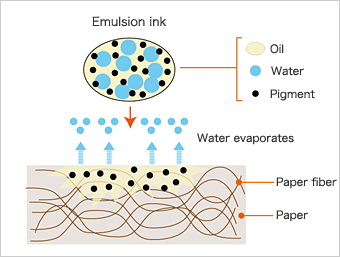

Immediately after printing, the oil and water in the emulsion ink begin to separate. The only part that remains within the paper is a portion of the oil and the pigment. The optimization of the oil, water and pigment balance, together with optimal conditions allows high-quality and dense printing, minimizing bleeding or smearing.

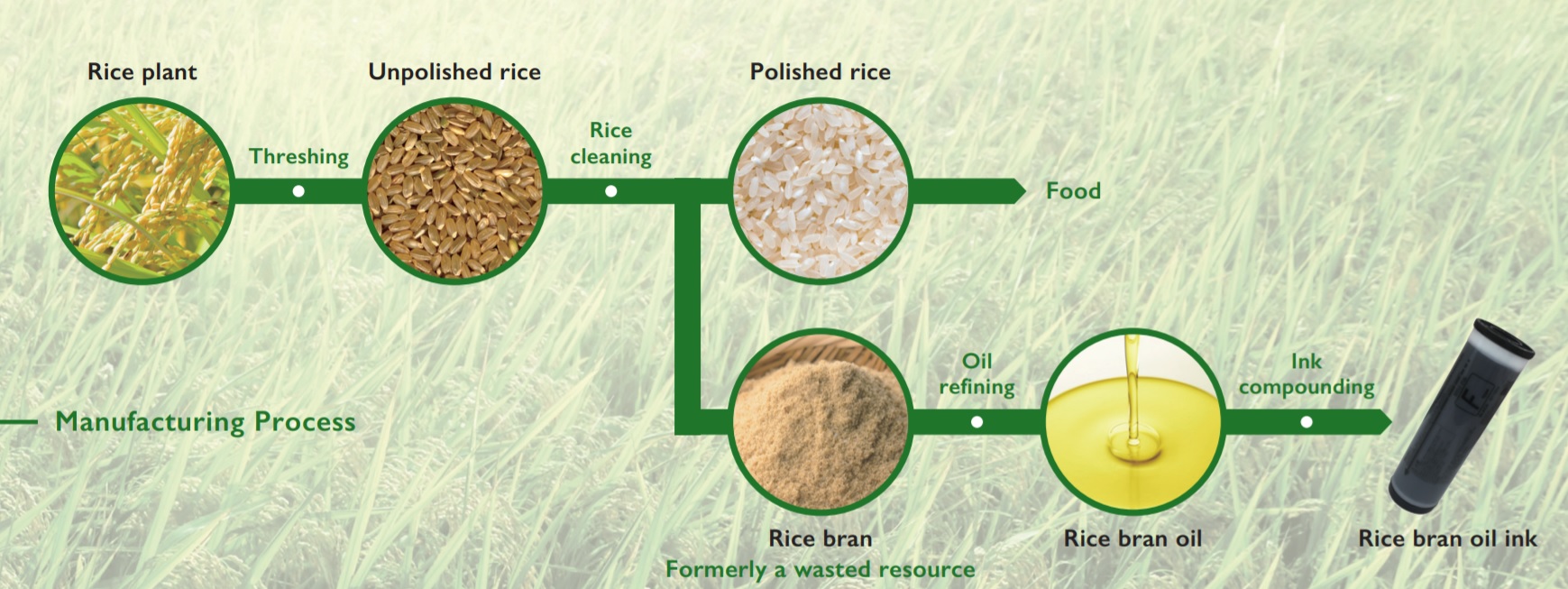

Rice Bran Oil Ink

The rice bran oil ink contributes to environment sustainability. Rice bran, which would be otherwise wasted, is a raw material with no VOCs, so after the oil is extracted for the ink. It can subsequently be used as fertilizer or animal feed.

RISO adopts rice ink using rice bran oil. As the used of rice bran are sourced from domestically produced rice in Japan, the transport distance of the raw materials necessary for ink production is shorter than soybean oil ink using mass-imported soybeans from overseas, and transport-related CO2 emissions are greatly reduced.

In addition, rice ink does not easily deteriorate over time, reducing alteration of printed parts, and extending the recommended expiry date.

Various colors including gold and fluorescent

RISO offer inks in 21 standard colors and 50 custom colors. Order-made colors such as corporate colors are also available. Riso has also succeeded in developing the world’s first gold and fluorescent inks for Digital Duplicator.